Systems and machines for producing and manufacturing the components used in the footwear production cycle (shape, die) and the components that are part of the shoe (toe puff, stiffener, insole, heel, sole, welt, strips, small metal parts, etc.)

B - Shoe machinery

B06 - Components preparation machinery

B06.01 - Skiving machines for toe caps

Machine which reduces the thickness of the toe puff edges in accordance with the design requirements of the shoe model. The skiving or "bevelling" edge is made by cup-shaped knives that rotate at high speed and with a preset inclination. The operation can be hand-operated or by templates. Versions from the traditional to computerized.

B06.02 - Stiffeners production machine

Machine series for the manufacture of stiffeners. These include: multiple machine for skiving, pebbling and stamping; stiffener rolling machine; pre-preforming and preforming; gluing, drying and packing line.

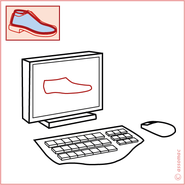

B06.03 - Insoles CAD-CAM systems

Insole CAD design software with different functions according to the defining of the lines, virtual prototyping, series development, and MIS, etc.. The CAD/CAM (Computer-Aided Design / Computer Aided Manufacturing) are used to get projects directly into instructions for the machinery.

B06.04 - Insoles cutting machines

Cutting systems press with die or oscillating knife; the first also available to perform automatic sheet loading, alignment and feeding.

B06.05 - Skiving machines for fibreboard heel socks

Machine with automatic cycle that performs the removal of material by operating with rollers arrays that reproduce exactly the surface you want to achieve with the required thicknesses in different zones.

B06.06 - Metal shanks applying machines

Continuous charger of the heel-sock and the metal shank and their assembly through tips self-riveting “braces” or one or two eyelet rivets.

B06.07 - Insoles preforming presses

Press for insole shaping. Configurations: manual and automatic feeding and unloading. It is equipped with a mold which has the basic geometry of the bottom of the model last.

B06.08 - Injected shank to insole systems

Automatic line for the insole cutting and section splitting till established measures. Then a rotary injection machine does a injected plastic shank welded to insole.

B06.09 - Heel CAD-CAM systems

Heels CAD design software 2D-3D with different functions according to the defining of the lines, virtual prototyping, series development, and MIS, etc.. The CAD/CAM (Computer-Aided Design / Computer Aided Manufacturing) are used to get projects directly into instructions for the machinery.

B06.10 - Injected heels systems

Moulding machine for ABS (Acrylonitrile-Butadiene-Styrene) heels using moulds in which is inserted a shape cut “band” in order to heel covering before injection, further metal insert can be applied for the realization of stiletto heels.

B06.11 - Heels processing machines

Machines for manufacturing traditional heels: two rollers cementer for lifts; assembling press for lifts, toplift application; milling machines, heel abutting, hollowing machine, etc..

B06.12 - Heel working CNC systems

Work station for wooden or leather board heel profiling, pitching, digging.

B06.13 - Sole CAD-CAM systems

Sole CAD design software with different functions according to the defining of the lines, virtual prototyping, series development, and MIS, etc.. The CAD/CAM (Computer-Aided Design / Computer Aided Manufacturing) are used to get projects directly into instructions for the machinery.

B06.14 - Sole processing (common working)

Set of machines, such as: scouring-buffing machine for soles on grain side; flesh side scouring machine; stamping, numbering and marking machine with automatic feeder and collector; sole edge pre-trimming and trimming machine; sole cleaning-polishing machine; sprayer and marking sole decorations press; dryers; equipment for execution channel, grooves, ornaments, trimming cutter for soles with inserts; dyeing edge machine. Process leather, tunit, synthetic, EVA unit sole.

B06.15 - Prefinished soles processing machines

Set of machines specific to the soles called "pre-finished" mainly used for men classic shoes or women low-heel shoes. They include: equipment for channeling, grooves, ornaments execution; sole and welt cementing systems; welt attaching; welt chamfering and pressing machine.

B06.16 - Wall soles processing machines

Set of machines specific to wall soles (“box”, opanka), mainly used for shoes where the sole is integrated to the line of the upper. They include: edge growing, Jourdan skiving and shaping; edge setting; presses for shaping and skiving reducing machines.

B06.17 - Trimming machines to copy and groove soles

Milling machine for EVA, micro-porous rubber, cork and imitation leather (SALPA) or masonite wedges. The milling operation is performed by copying from a tamplate (shape), the exact shape of the sole to be obtained. Can processing on different layers/components of the sole which are then bonded together.

B06.18 - Welt processing machines

Traditional or automatic system for the leather, leather board, synthetic welts manufacture. Machines for bands preparation; strip cutting and winding on spools; channel execution and opening; cement coating; channel attachment of filling and closing; stitch marking; painting; groove for Goodyear sewing; grooving turning; seaming; slotting with zig-zag welt cutting; roughing lower base.

B06.19 - Welt attaching machines to sole

Systems to spread adhesive on soles and welt and their joining, welt chamfering and pressing.

B06.20 - Strips, edges, mignon machines

Range of machine to process and prepare strips, edgings, mignon such as strip cutters, cementing, seam presses, skiving, forming, winding spooling, plaiting machines, etc.

B06.21 - Die-cutter processing machines

Range of machines to implement the cutting steel dies. There are shearing, bending, punching, abutting, broaching, grinding, welding machines, etc.

B06.22 - Metal small ware machines

Plants to produce small metal alloy of zinc or tin by centrifugal casting. It involves the use of silicone rubber for the preparation of molds, as negative counterform obtained from the original positive, to be filled subsequently by casting, using some materials such as white metal alloys, low melting point, or the resins (epoxy, polyurethane or polyester), gypsum, etc.. The plants performs the realization of buckles, jewels, buttons and fashion accessories.

B06.23 - Last CAD-CAM systems

Last CAD design software 2D-3D with different levels of functionality to the definition of the style lines, virtual prototyping model, series development, production management, etc.. This is CAD/CAM (Computer-Aided Design Computer Aided Manufacturing), which allow to convert projects directly into instructions for the machinery.

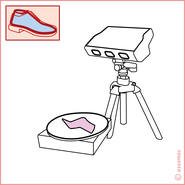

B06.24 - Last digitizers

High precision equipment that automatically provides a high number of points in volumetric structure of the last in order to have its virtual image. Mechanical type, luminous technology, etc.

B06.25 - Last production machines

Machines for last production from rough shape moulding to first and finishing roughing and joint insertion. Version from manual to numerical control.