Machinery, equipment and accessories for upper parts manufacture and their joining by sewing (the top of the shoe).

B - Shoe machinery

B02 - Upper preparation and stitching machinery

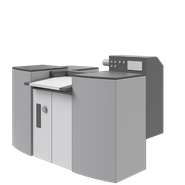

B02.01 - Splitting machines

Machines that equalize the thickness of the shoe upper leathers removing material from the flesh side. It can operate edge skiving by means of templates, to be made following a defined geometry. Average working width between 400 and 600 mm.

B02.02 - Stamping machines

Machine used to stamp the identification of shoe upper parts. Several versions are available, starting from mechanical to computerized and from hand-operated to automatic and digital control types.

B02.03 - Skiving machines

Machine which reduces the thickness of the leather on the parts that constitute the shoe upper in accordance to the requirements of the shoe model. The bevel or "bevelling" edge is made by cup-shaped knives that rotate at high speed and with preset inclination. The operation can be hand-operating or by templates. Traditional or computerized versions are available.

B02.04 - Upper reinforcements applying machines

Machine configuration with rotary plate, book-closure plates hinged or pressure roller for hot assembling of reinforcements of various types and material to the upper. Versions from manual to mechanized.

B02.05 - Edge taping machines

Several configurations available, of this type of machine that applies self-adhesive reinforcement tapes on the edge of shoe uppers or on portions of shoe uppers. They can perform different additional operations such as stitching flattening, edge milling and automatic cutting tape.

B02.06 - Vamp crimping machines

Crimping and shaping machine suitable for single-piece bootlegs. It is equipped with two vertical plates within which moves the arm that drags the upper forcing it to slither between the plates.

B02.07 - Plating and printing machines

Machine equipped with work table and striking plate with matrix on which is printed the design to be realized. Performs effects of plating, embossing and also drilling and shearing. Versions from manual to automated.

B02.08 - High-frequency printing systems

Machines that produce high frequency energy that heats and softens the cover of the shoe upper performing particular relieves by pressure on the mold. Versions from simple single-user to the linear continuous production.

B02.09 - Punching machines

Machine that realizes a series of aligned holes along the edges or in array in the middle of the parts that make up the shoe upper. Machine equipped with a single punch needle and continuously fed. A peculiar type of punch is that used to make holes for the crossing of the laces, that drills simultaneously the shoe upper on both sides.

B02.10 - Edge folding machines

Machine that folds the edge -already skived- parts of the shoe upper, using thermoplastic adhesive and operating cutting measures along concave and convex curves. Versions level from simple to complex in the computer control of process parameters.

B02.11 - Toe cap attaching machines

Machines in versions from simple irons, to flat or roller presses for applying cold/hot reinforcements on the shoe upper.

B02.12 - Lining-upper cementing machines

Machines and equipment for gluing on reinforcements and parts of shoe uppers and lining. Spray and roller versions.

B02.13 - Pleating machines

Machine running straight or curved pleats to create patterns of decoration of uppers for footwear, parts and components.

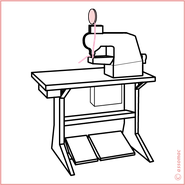

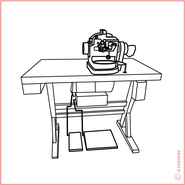

B02.14 - Flat-bed sewing machines

Sewing unit including supporting surface for the material. The unit can perform several stitch types (knotted, single or double chain stitch, overcast, zig-zag), different types of sewing (one needle, two needles, straight, zig-zag) and with different transport systems (feed dogs, feed dog and needle, needle and feed dog-legs, others).

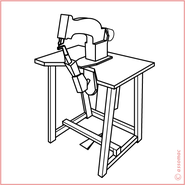

B02.15 - Arm-type sewing machines

Stitching unit with arm type counter top for the material. The unit can perform several stitch types (knotted, single or double chain stitch, overcast, zig-zag), different types of sewing (one needle, two needles, straight, zig-zag) and with different transport systems (feed dogs, feed dog and needle, needle and feed dog-legs, others).

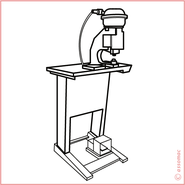

B02.16 - Post-bed sewing machines

Stitching system with support for the material column type. May run several different stitch type (knotted, single or double chain, overcast, zig-zag), different type of sewing (one needle, two needles, straight, zigzag) and different material feed system (simple with a feed dog mechanism; feed dog and needle feed; feed dog plus needle feed plus alternating presser feet; upper differential; others).

B02.17 - Mocassin type sewing machines

Sewing unit equipped with special stitching heads and templates. In the versions with overcast lockstitch and curved needle can carry out various types of seams.

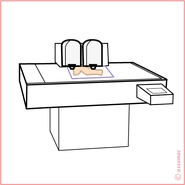

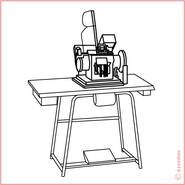

B02.18 - Seam beating of upper stitchings

Machine equipped with a long anvil support with a working plate, particularly suitable to beat and iron upper and boot seams.

B02.19 - Seam pressing and tape applying machines

The machine presses the seam by two pressing rollers and simultaneously applies a reinforcement tape of various widths on the seam.

B02.20 - Upper lining trimming machines

Machine equipped with a knife blade which oscillates and counterblade feeding device, suitable for trimming the linings of the uppers. Available in different versions depending on production needs.

B02.21 - Strobel insole applying machines

Solid frame structure machine for chain stitching joining the lower edge of the upper with insole ("slip-lasting" method).

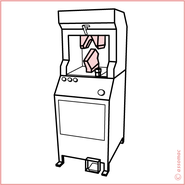

B02.22 - Eyelets, rivets, hooks, rings, vis applying machines

Machine with pressure matrix for the application of eyelets, rivets, nailheads, hooks, rings, vis. Ranges from fully manual handling up to the automatic feeder of small parts system and automatic material feeder to measured steps.

B02.23 - Automatic programmable machines to realize ornaments by small parts

Numerical control machines that realize ornamental drawings by vectorial files. They are equipped with one or more application heads, in order to apply various metal decorations like nailheads, eyelets, rivets. The leather is fixed on templates specially prepared; completely automated.

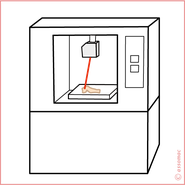

B02.24 - Laser systems

The laser systems for the leather use a CO2 source; the power can be normally between 50 and 500 Watt. They are usually equipped with special software able to use vector files, and check the many processing parameters: power, speed, frequency. The laser systems are mainly of 2 types: plotter and galvanometric. In the second one the laser beam is controlled by special mirrors, moved with great speed and accuracy the highest quality results and is used for engraving, perforation, raster photo effect, cutting.

B02.25 - Vamp pre-forming machines

Pressing machine equipped with suitable shaped mould in hot station and, if present, cold station. It can give a bend on the front part of the flat upper such as to make it adhere easily to the last model.

B02.26 - Upper lacing machines

Machine where the uppers with eyelets are laced up to a predetermined distance. Knots and thread trimming are done automatically.

B02.27 - Boot turning-out machines

Pneumatic machine that overturn the uppers of boots. Configurable for every leg height of boot.

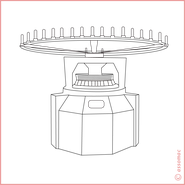

B02.28 - Machines for knitted uppers

Series of specific machines for the preparation and processing of uppers using flat or circular knitting machines.