Systems, machines and equipment for processing the lasted shoe bottom to make up the footwear.

B - Shoe machinery

B04 - Lasted shoe bottom working machinery

B04.01 - Lasted shoe roughing machines

The machine performs the roughing of the lasted shoe, works with a circular steel brush, that is set in order to work tangentially to the lasting surface. Particular version is that roughs the profile of the uppers mounted on a last for the application of the shaped sole. The operation cleans and prepares the part which the adhesive will be deposited on for bottom application.

B04.02 - Sole roughing machines

Roughing machine for soles in different materials and shapes. The sole must be sustained and pushed against the tool with a little pressure by the worker and it must be also guided during the work. The tool is a carbide cutter or abrasive rings Particular version is that roughs the profile of the shaped sole. The operation cleans and prepares the part which the adhesive will be deposited on for bottom application.

B04.03 - Lasted shoe-sole cementing systems

Range of machines and equipment for the cement application on the shoes bottom and on the sole before their final assembling. Technical solutions with spray nozzle, rotating brush and roller. Manual control and management.

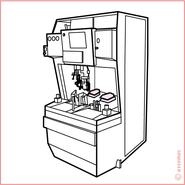

B04.04 - Lasted shoe-sole automated cementing systems

Programmable and automatic shoe lasted bottom and sole cementing systems, versions with the "vision" or programmable axes. Technical solutions with spray nozzle or rotary brush. Present a configuration for roughing and cementing the side wall sole shoe.

B04.05 - Multifunction machines for lasted shoe

Machine equipped with programmable axis, making scouring, pounding, roughing cycles on the bottom already assembled depending on the tools installed.

B04.06 - Dryer reactivators

Machine for drying and reactivate the cement by means of heating, in versions hot air and infrared. Static and tunnel configuration.

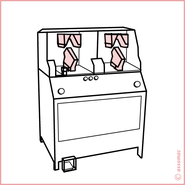

B04.07 - Sole attaching presses

After cement deposition and reactivation, the shoe lasted and the sole and holding in position using dedicated press systems. Configurations from the two arm pressure tools, sector pads to follow the lower line of the shoe up to pressurized self-shaping pads. The pressing action is guaranteed by various solutions: mechanical, pressurized air or vacuum systems.

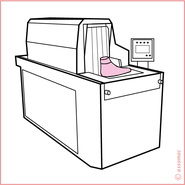

B04.08 - Chill setters

Cooling machine to stabilize lasted shoes after the sole application. Cell static and conveyor belt configuration with functions controlled by microprocessor.

B04.09 - Brushing machines for glue removing along the edge last

This machine, through a rotating brush, allows removing the excess of cement on the edge of the shoe and providing the right cleaning of the shoe even in the most difficult points. Optional accessories for anti-shroud liquid application.

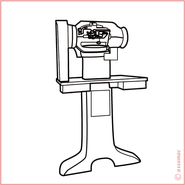

B04.10 - Heel seat pounding machines

Machines that provide leveling and edging heel seat using tools such as plat and roller. This operation can guarantee the fine tune coupling between the shoes components and improving the quality of the shoe. The matrix, with profiles similar to the heel to be applied, can be either fixed or interchangeable.

B04.11 - Fitting heel beating machines

Hammer swing machine that levels the line of heel-seat to the heel already assembled on the footwear.

B04.12 - Last pulling machines

Equipment based on locking pin and cushion pads for extracting last from footwear. Machines available for a range of lasts: fixed shape, the "V" and/or last with hinge joint.

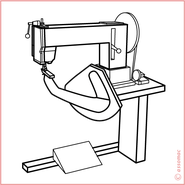

B04.13 - Blake sole sewing machines

Strong frame sewing machines make blake stitching, inside the lasted shoe, in order to ensure the direct cohesion between the upper, insole and sole.

B04.14 - Wall sole sewing machines

Sewing machines to perform the side stitching between upper and sole, inside the lasted shoes, wall sole (opanka) shoes.

B04.15 - Sole sewing machines curved needle

Sewing machines in various configuration to perform interventions on lasted shoe in order to ensure the direct cohesion between the upper and/or insole and/or sole with the possibility to simultaneously apply the welt. According to the configuration the shoe assembling is rapid, goodyear, ideal, san crispino.

B04.16 - Goodyear processing machines

Range of specific machines for goodyear shoe assembly. They include: rib-tape applying, staple side lasting, upper trimming, welt stitching, welt beating and stretching, refresir trimming, heel welt stitching machines.

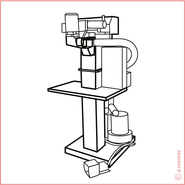

B04.17 - Heel prefixing - nailing machines

Presses that through the insertion of screws or nails secure the heel to the assembled sole. According on the type of footwear and its quality, this operation required a pre-fixing and/or permanent fixing. Solution from manual to fully automated.

B04.18 - Shoe quarter reforming machines

The machine reforms the quarter, giving evidence to its shape. In this working the quarter is first reactivated by means of a special heated mould, and then it undergoes a cold stabilization.

B04.19 - Relasting machines

It is able to relast tubular moccasin uppers or shoe lasted without physical stress for the operator.

B04.20 - Channeling machine

Range of machines suitable to perform the channel (engraving which forms a lip) on the lasted sole; open or close the channel lips and in meantime trimming and/or creating a small channel to perform the bottom stitching.

B04.21 - Trimming machine

Machine with rotary axis equipped with tool cutter for milling or cutting the bottom of the shoe lasted; useful for reduce the imperfections of the sole and heel profile.

B04.22 - Band scouring machines

Machine equipped with an abrasive paper band stretched among two wheels; designed to remove surface layer from the semifinished product. Useful for finishing and shoe lasted bottom processing.

B04.23 - Heel top piece attaching presses

Machine used to secure the top piece to the heel by pressure, in order to protect the heel from contact with the floor. A very abrasion resistant material.