Systems, machines and equipment for the final shaping, coloring and finishing of leathergoods.

C - Leathergoods machines

C04 - Shaping, dyeing and finishing machinery

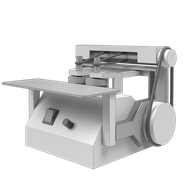

C04.01 - Diecutting-shaping machine

Presses equipped with head hollow punches that allows to scouring the shape of the tip and the holes along the center line or the shape of the back. In addition punching the seat pin buckle, hot stamping of logos and alphanumeric codes. Machines with: variable power cut , structure of the cutting plane and punches head; these can work in manual, semi-automatic or automatic.

C04.02 - Edge working machine

Operations such as trimming, milling, grinding, polishing, brushing and polishing or filings are present in particular for finishing cut edges almost always present on the belts, often on bags and small leather goods in general.

C04.03 - Roller decoration printer

Machines for printing and engraving ornamental motifs of belts by system with roller matrix or by flat press and linear molds.

C04.04 - Buffing-brushing machine

When the material of the edges occurs porous and the small roughness are not removed, then it is necessary to intervene with an action of polishing to make the surface smooth. This can take place before or after brushing, depending on the quality of the material. The sanding tool to be used is an abrasive wheel that can provide the similar result obtained with very thin sandpaper grit.

C04.05 - Polishing machine

Treatment with natural waxes and creams are finalized to obtain various shades of light reflection and the repetition of polishing steps are widely used at this stage of processing of the product.

C04.06 - Dyeing system

The interventions of staining for the models in the collection, incorporating parts sharp cut, serve to beautify and give that touch the artifact that makes it more aesthetically appreciable. These operations can be obtained with machines that require different interventions by the staff regarding time and skill, and such equipment is normally divided into two groups: those manual and semi-automatic ones.

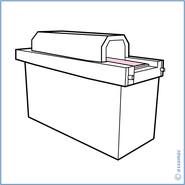

C04.07 - Color drying oven

Immediately downstream of the dye-edge machines, in the production laboratories of leather goods some ovens or dryers are installed to allow the semi-finished parts to proceed through the next step, in fast sequence. A special configuration of these units is used to dry the color applied on the edges of parts of bags and folders or already assembled final products, such as bags, folders, briefcases and small leather goods in general. Another unit type is represented by a configuration for horizontal and vertical belts and the like.

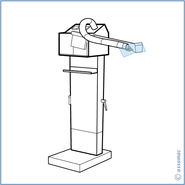

C04.08 - Edge polishing machine

Hot polishing edges achieved through glazing-blocks for glazing responding to the profile to polish. The versions with rotating tools or with vibration motion are used in the production of belts, shoulder straps and strips in general.

C04.09 - Metal small ware machine

Plants to produce small metal alloy of zinc or tin by centrifugal casting. It involves the use of silicone rubber for the preparation of molds, as negative counterform obtained from the original positive, to be filled subsequently by casting, using some materials such as white metal alloys, low melting point, or the resins (epoxy, polyurethane or polyester), gypsum, etc.. The plants performs the realization of buckles, jewels, buttons and fashion accessories.

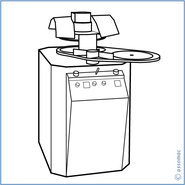

C04.10 - Eyelets-rivets applying machine

Machine with pressure matrix for the application of eyelets, rivets, hooks, rings, vis. Ranges from manual handling up to the programmable and automatic solutions.

C04.11 - Stamping machine

Performs hot stamping and numbering or with the use of golden ribbons or colored, to imprint letters, words and numbers for the identification and traceability of the product and mark prestigious logos to validate content and price. The operation requires accurate and timely preparation of the machine to get a flawless, clear and well marked.