Machinery, equipment and accessories for assembling components parts on leathergoods and make the final finishing.

C - Leathergoods machines

C03 - Assembling and packaging machinery

C03.01 - Cementing system

Machinery, equipment for applying adhesive cement on reinforcement, right side and lining parts. Type of configurations spry and roller

C03.02 - Assembling press

Machines and equipment designed for assembly processes, for joining the front sides and linings or for reinforcing and consolidating parts of manufactured items, can operate either cold or hot - in this last case, for instance, intervening on semi-finished articles treated with thermo-adhesives or polyurethane cements to reactivate them. From a structural and operative point of view, the feature of the machines can be: rotary plates, or alternatives, with a vertical pressing movement; plates hinged along one side and with a folding door construction; presser roller with continuous feed.

C03.03 - Glue drying oven

Machine for drying and reactivate the adhesive cement through heating system; various configuration are available with hot air and/or infrared lamp.

C03.04 - Edge trimming machine

Prepare the edge of parts or all of the geometry of the contour of leather goods before the start of the finishing phase. The trimming operations are finalized particularly on belts, shoulder straps and bands using cutting tools such as saw blades or knives.

C03.05 - Sewing machine

Stitching system with a flat table support for the material. May run several different stitch type (knotted, single or double chain, overcast, zig-zag), different type of sewing (one needle, two needles, straight, zigzag) and different material feed system (simple with a feed dog mechanism; feed dog and needle feed; feed dog plus needle feed plus alternating presser feet; upper differential; others).

C03.06 - Seam press

Specific equipment that performs the flattening, after seam, edge to edge of the sharp cut parts spliced as an open book.

C03.07 - Special sewing machine

Post bed sewing machines is a family of sewing machines specially designed for specific process and built for leathergoods operating process to transform a two-dimensional semi-finished piece into a three-dimensional one. The range of those machine include items like: machine vertical column type able to perform a rotation of 360°, horizontal tilting column, automatic machines for sewing belts and for the application of whole or half buckles, and passers.

C03.08 - Automatic sewing system

Automatic sewing machines intended for the realization of stitching for decorative purposes, joint seams, applications of appliqués with logos or of other sorts, or fasteners, whose operations are controlled electronically through a microprocessor. Usually the automatic sewing machines operate by moving horizontally a work table, onto which the piece in production is placed, along a horizontal plane, under a fixed stitching head fitted with a vertical movement in synchronism. The interventions are programmable, and the operator’s task is limited to loading pieces and starting up the stitching unit.

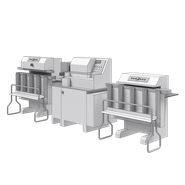

C03.09 - Belts processing plant

The production (of these types) of artifacts made of synthetic material can be set-up adopting a "continuous" system process organization. The synthetic material is supplied in rolls or spool usually up to 1400mm wide that can be cut with appropriate equipment, named “slitting” into several parts and spooled. Starting from material in coils in the two types provided, one for the right of the article and the other for the lining, you can arrange an island work for the obtaining of belts, straps and the like.