Supplier of engineering, services suppliers, equipment and components, in order to design and build production systems and industrial plants.

A - Tanning machinery

A09 - Engineering

A09.01 - Feasibility study and plant design

Preliminary planning and verification of economic-environmental conditions for the realization of tanning plants.

A09.02 - Turnkey plant and tannery start-up

Turnkey, complete supply of tanning plants. Executive planning, Installation, Testing and Startup.

A09.03 - Dosing & Mixing centralized plants

Mixing, dosing and stocking implants; for liquid or semi liquid chemical tanning products; for wet and finishing phase of the process. Consist in remotely controlled systems that can provide the delivery and conservations of mixing products through continuously recycling . The dosing systems can assure the precision and repeatability of the recepies of tanning process. The implants are equipped with appropriate containment tanks for environmental purpose.

A09.04 - Plants for bath recycling and filtration.

Centralized integrated plants and systems for production lines; such as drums line specifically dedicated to water mixing and recycling and filtering of tanning baths. This equipment can give a direct contribution in resource optimizations (water, energy) and relevant reduction on pollutions into waste waters.

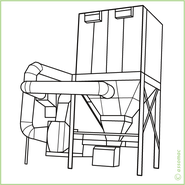

A09.05 - Air filtration and dust collector plants

Equipment for aspiration, dust abatement and toxic gas processing. Solutions are available for drums and the subsequent treatment of H2S. Centralized dust extraction processes for dry shaving, sanding and dusting etc.

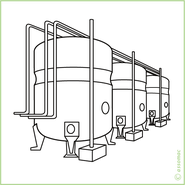

A09.06 - Chemicals storage reservoire

Storing Systems for liquid and solid Tanning Chemicals used in the process and systems for collection, storage and homogenization of tanning waste water.

A09.07 - Compactors and collectors

Systems for the collection, storage and volume reduction of tanning solid waste, such as: fleshing, shaving, boffing dust, etc. They are compacting screw, plates pressings, mechanical kinematic mechanisms, pumps etc.

A09.08 - Climatic Store Chambers

Climatized hides and skins warehouses. Dimension will be calculated according to the tannery production program.

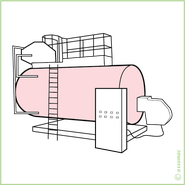

A09.09 - Boilers and Heaters

Centralized heating systems for water by electricity, combustion (methane, gas) or other source.

A09.10 - Pneumatic plant vacuum & air

Plants for production and distribution of compressed air. They consist in a compressor, a storage tank and a distribution network to feed machines and parts of machines using power pneumatic.