Ground or transportable plants for treatment of solid, liquid and air wastes in order to reduce the concentration values of the pollutants within the limits established by current legislation before discharge into the environment.

A - Tanning machinery

A10 - Waste treatment plants, Containerized systems.

A10.01 - Waste Water treatment plants

Effluent treatment plants (ETP) locally builded. Usually the water line includes three main stages: pretreatment, treatment oxidative biological, additional treatments including sludge separation.

A10.02 - Sludge treatment plants

Sludge treatment units, separated in the phases of sedimentation. The main purpose is to eliminate the high content of water in the sludges and to reduce its volume, as well as to stabilize (non-degradable) in order to reduce the environmental impact at the final stage.

A10.03 - Hazardous Waste recovery plants.

Treatments and recovery plants for hazardous waste. The Chrome recovery into tanning waste water based; on flocculation/precipitation concept as salt that will be filtered reused in the process. Treatment plant for water from spray cabin fused on elimination of trapped chemical products; confined washer systems for tanks or reservoir.

A10.04 - Solid screener plants

Screening systems for the waste water in order to remove solid objects and reduce suspended materials by floating. It is classified in fine, medium and coarse and is made by screw systems, drum or belt filter.

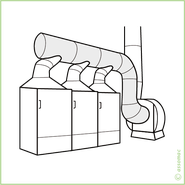

A10.05 - Air treatment plant

Painting dust filtering plants. Systems removal of pollutants from exhaust gases for keep under control the working environmental conditions for workers health. They are present in spray booths and stages of wastewater treatment and sludge where are generated odors and toxic atmosphere.