Equipment dedicated to raw hides processing, from the rough stage up to half-processed product (wet blue). The flow path of tanning process is a sequence of chemical operations facilitated by mechanical actions (beam house); mainly, soaking for rehydration, liming for unhearing, deliming, bating, degreasing, pickling and tanning. The process flow path is crossed by mechanical operations for size optimization: specifically: flashing, lime splitting or damp tanned (wet blue) splitting and shaving. Finally a semi processed stable products (wet blue) is obtained; it can be stored and marketing as it is or the process can be extended to a post-tanning phases, retanning, fatliquoring and dyenig operations, to reach an semi-finished product (crust).

A - Tanning machinery

A01 - Beamhouse machinery

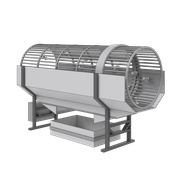

A01.01 - Desalting machines

Machines for the mechanical removal of the exceeding salt of conservation. This operation contributes to reduce the water consumption during the rehydratation phase. The machines are complete with a rotating cylindrical sieve where the raw hides are loaded to separate the salt.

A01.02 - Paddles

Soaking machines for raw skins (sheep and goat, or others) and furs. Substantially this bathtub, made of bricks, concrete, wood, or steel, is a rotating mechanical mixing mill for softness.

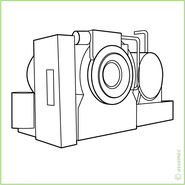

A01.03 - Washing machines

Machines used for degreasing of hides/skins by means of solvents. The structure of the machines are similar like the industrial washing machine for textile, for the use with solvents’ recycling and recovery systems

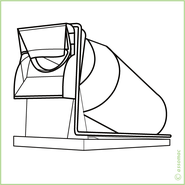

A01.04 - Mixers

Mixers (similar type like concrete mixer) for the greening of the skins, for large volumes of product, with angled blades to mix the hides/skins with water. The Mixers are provided with a hopper for loading the products.

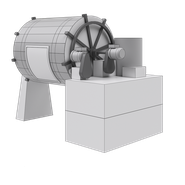

A01.05 - Drums (wood, s.s., plastic)

The drums are watertight cylindrical containers with variable size dimensions where the hides/skins are processed according to phase sequence of tanning process. Beam house; soaking for rehydration, liming for unhearing, deliming, degreasing. Subsequently pickling and tanning steps and finally utilized for retanning, fatliquoring and dyeing. The mechanical action on the hides, due to the rotations, maximize the skin's absorption of chemical compounds and induce the process reactions. The systems can be built using various materials: wood, stainless steel, polypropylene, etc. and fully automatized through control devices (es. rotation, temperature)

A01.06 - Sulphide Applicators

Automatic device for coating some depilatory products (pastina) on the hides/skins with hair; the operation is performed by means of a doctor blade coating placed above a continuous strip on which slide the hides/skins.

A01.07 - Unhairing machines

Mechanical devices for shaving hides and skins treated with depilatory products (pastina). The systems are equipped with rotating cylinders that allow the removal of the hair through a tensile force exerted on the surface of the hides and skins.

A01.08 - Dewooling machines

Dewoolling rubber rotating cylinder machines, for the removal of wool from sheep and goat skins, suitable to the recovery of the wool.

A01.09 - Fleshing machines reciprocating and continuous

The fleshing process can be carried out using reciprocating machine, double introduction or continuous, single introduction. In both case the process consists of a leather passage between contrasting system such as tow rotating cylinders, one with spiral blades that operates the fleshing. The process is useful to remove the residual fleshing, and provide to make uniformity of hides thickness.

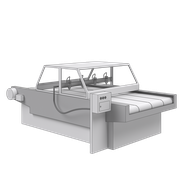

A01.10 - Lime splitting machines

The splitting process of the hide in horizontal layers allows to reach the desired thickness and simultaneously to recover a byproduct (split) which is processed in a same way like the hide from which it derives; this operation can be done at different steps of the manufacturing process. The splitting in lime is practiced on large hides (bovine) using the machines that are equipped with a circular band knife mounted on wheels, specifically designed to facilitate the hide introduction. Equipped with micrometric precision systems, such as the insertion table inclination and blade position, that ensure the thickness adjustment with very hight accuracy. The blades are automatically rebladed through grinding stones mounted on cart system.

A01.11 - Wet splitting machine

The splitting process of the hide in horizontal layers allows to reach the desired thickness and simultaneously to recover a byproduct (split) which is processed in a same way like the hide from which it derives; this operation can be done at different steps of the manufacturing process. The splitting in wet phase is practiced on tanned hides using the machines that are equipped with a circular band knife mounted on wheels, specifically designed to facilitate the hide introduction. Equipped with micrometric precision systems, such as the insertion table inclination and blade position, that ensure the thickness adjustment with very hight accuracy. The blades are automatically rebladed through grinding stones mounted on cart system.

A01.12 - Wet Shaving machines

Shaving is a production process for final thickness adjustment that can be done in wet phase such as in finishing stage. The machines are working on the flesh side of the hides/skins which remove the excess material and make uniform the thickness of hides/skins through the use of sharp blades mounted on a spiral rotating cylinders while the grain side faced the pressing roller . The constant sharpening of the blades is ensured by a mobile carriage of grinding wheels.

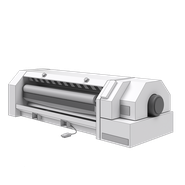

A01.13 - Sammying and stretching press machines

The sammying machines are used in the tannery to squeeze the hides/skins. The combined action of cylinders covered by absorbent material and pressure the liquid of the bath etrappend into the fibers are removed . The sammying machine model are alternative type (two action) or continuous (single action).

A01.14 - Setting out and sammying machines

This processing is carried out through the action of a set of rollers including a roller blades, rounded, said "bladed", which acts with variable pressure against the pressing roller, compressing and squeezing the skins so as to remove a substantial amount of water of which the skins can be impregnated; widen and flatten the hides; eliminate as much as possible roughness, smooth and make the skins very flat.

A01.15 - Moisturing machines

Machines for humidifying: have the function to rehydrate the skin to ensure the moisture content necessary to carry out the stages of finishing. The operation can be automated through a mechanical system consisting of a series of spray nozzles and a carpet conveyor on which the leather is loaded.