Following the tanning steps, the skin should be dried to an optimum internal moisture content. This process must be carried out under controlled and reproducible environmental conditions for it to be insured the yields of the leather surface and the physical characteristics of the product. This can be achieved either by hanging the tanned leather for a few hours in the appropriate tunnels, or through vacuum driers, or by drying with toggling systems, or other dry methods, according to the type of product and of the finishing type of leather that must be obtained.

A - Tanning machinery

A02 – Drying machinery

A02.01 - Dry chambers (in batch)

Drying air-conditioned rooms in which the pieces of leather are placed on special pallet and conditioned at a controlled temperature and humidity. Forced ventilation systems provide the homogeneous diffusion of temperature and humidity that are regulated by the on board control panels.

A02.02 – Toggling machines

Toggling frame dryers, the leathers are under tension drawn and suspended by means of special toggle clips that lock in a frame without piercing the leathers. In some cases, dryers, used for the purpose, are made up of frames that run on chain conveyors from inside to outside of the drying chamber, and each frame supports a perforated sheet metal that can be folded in order to toggles the leathers on both sides of the frame; in other cases the frames are automatically pulled through a rail system, or they or are constructed in the manner of a continuous metal conveyor. The expansion systems can be automatic or manual, and the toggling systems also can be manual or automatic.

A02.03 - Vacuum dryers

Vacuum drying is a process that consists in positioning the entire hides/skins or half hides out of metal plates, hermetically closed by a cover. The drying is achieved by a combined action of heat and pressure reduction between the floors of work, which allows to obtain the fast evaporation of water at lower temperatures. The drying conditions are adjustable according to the characteristics of the product to be processed through the control systems on board.

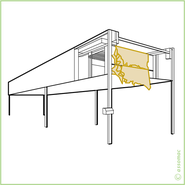

A02.04 - Drying tunnel with overhead chain

The drying tunnel are metal boxes suspended roof of manufacturing plant to optimize the space. The leathers are placed on metal rods and are transported inside tunnel by way of a chain. The tunnel is fed to heated air at adjusted temperature and humidity. Climatic conditions contribute at the natural evaporation and conditioning while maintaining a constant degree of humidity. In addition, the handling with overhead chains used to move the product in production areas even far from each other.

A02.05 - Conditioning system

Systems fed with heated air with balanced temperature and humidity, equivalent to a climatic chamber to perform operations of seasoning of the product. The leather, from medium to large size, is placed on special supports or rods and inserted into the system by means of a conveying chain. The environmental conditions are kept controlled to stabilize and consolidate the chemical products used for tanning.