Handling and logistics in the factory, automation and robotics.

A - Tanning machinery

A05 - Handling and automation

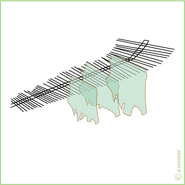

A05.01 - Overhead chain

System for leather moving along to tanning manufacture, used in both case for the semi and finished product are constituted by a transport system equipped with special metal bar for leather and anchored on the ceiling of the productive structure. In tanneries where climatic conditions, both daily and seasonal, are highly variable these systems are often combined with drying tunnel to ensure seasoning of the product at the temperature and humidity under control.

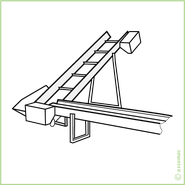

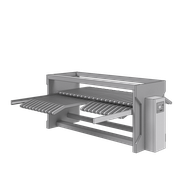

A05.02 - Loading and Unloading Systems

In case of large dimensions skins are processed the loading and unloading of the drums can be facilitated and simplified by systems of handling of the product. Consisting of conveyor belts or lifting systems these solutions allow the automation of the process and make the job safer for operators. The most common applications are transferred the raw hides from the warehouse to the area of liming, the pelts to the tanning phase and tanned to splitting or samming area.

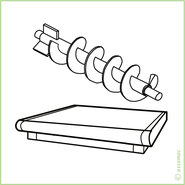

A05.03 - Belt and screw conveyors

Continuous conveyor systems, allow the transfer in continuous the semi-finished or finished product along the process path.

A05.04 - Stackers

Automatic machines to stack the skins, to automate the factory logistics between the different process operations.

A05.05 - Leather Scissor lift and tanks

Platform lift for leather piles stocking. Tanks for drum discharge.

A05.06 - Sorting lines

Automatic device to select and stack the skins through the production chain

A05.07 - Rolling-up machines

Automatic systems that can provide the similar manual procedure for the preparation of bundles of finished leather.

A05.08 - Leather "horses" and Leather racks

Leather-holding stands with wheels (horse type) and trolley, or other system with permits the temporary stocking of hides or loading climatic chambers.