Machines and plants for the production of shoe parts and soles through injection or pouring of synthetic materials into suitable moulds.

B - Shoe machinery

B07 - Synthetic machinery and moulds

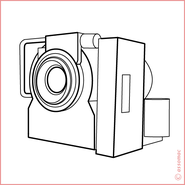

B07.01 - Thermoplastic injection machines

Plant in which the plastic material is melted and injected into a mould made according to the negative to be produced. It consists of an injection unit and a clamping unit. The injection unit has the task of heating, and then laminating the material and push it inside the mould, thanks to the action of a piston or a screw; while the closure unit has the task of keeping the mould closed.

B07.02 - EVA injection machines

EVA (Ethyl Vinyl Acetate) injection machine into a mould. The material expansion takes place during the the mould phase. For this reason the mould cavities are smaller than the final dimensions of the product.

B07.03 - Rubber injection machines

Process for direct moulding vulcanized rubber by injecting-pouring while the mould is closed for outsole inserts production or injection of rubber soles onto uppers.

B07.04 - PU injection machines

System for processing polyurethane by injection. The polyol and isocyanate are mixed by the injection screw before being pushed inside the mould. Can be adopted for the direct injection of soles on the upper.

B07.05 - PU pouring machines

System for processing polyurethane by pouring. The material flows down from the pouring head that is moved up the mould.

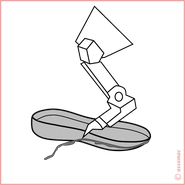

B07.06 - Injected sole automatic trimming

Robot for trimming the edge of the injected soles.

B07.07 - PU soles washing

Washing system for footwear soles made of PU, EVA and rubber before glueing or dye finishing.

B07.08 - Moulds

Specially designed block composed of two or more half-shells, which go to delimit an area of space with the outline of the piece to be obtained by injection or pouring.

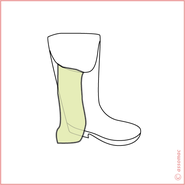

B07.09 - Internal linings

Internal linings made of fabric with the possibility of various fashion effect for injected shoes and boots PVC, TR, TPU, PU.