Systems, machines and equipment for the shoe upper and insole assembly and stabilization.

B - Shoe machinery

B03 - Shoe lasting machinery

B03.01 - Insole applying machines

The machine allows the insole fixing to the last by nail, hook, glue or sticky tape. It can be supplied with equipment to trim the insole.

B03.02 - Insole trimming machines

Machine with rotating blade and counter blade for trimming the insole along the edge of the last. Continuous sharpening device.

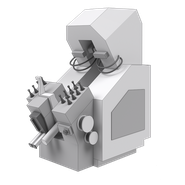

B03.03 - Backpart moulding machines

Defined "upper stiffener shaping" machine, it serves to pre-shape the material used for the reinforcement and to form a single entity of lining, stiffener and right upper side. The machine configuration can be in static or roundabout mode and are equipped with heated and cooled systems according to the needs.

B03.04 - Toe upper forming machines

Machine for shaping the toe upper; it consists of a heated station for the reactivation of the toe cup and of a station with aluminum last for shaping the toe of the upper. It makes the edge of the upper linear and ironed.

B03.05 - Upper edge roughing machines

Using roughing wheel, the machine removes the material in excess from the shoe upper (lining and toe cap); it levels them for facilitate the subsequent gluing operation during shoe lasting.

B03.06 - Moccasin ironing machines

Machine equipped with aluminum last or series of lasts, on which is inserted the shoe upper of the sewn moccasin for the lastingly stabilized them in the shape position. The last may be heated or provided with holes for the steam. Configurations from the simple position to the rotary; supplied with beater hammers.

B03.07 - Machines for humidifying upper and/or its parts

Moistening chamber for the leather shoe uppers, involving both the external and the internal parts; lining and other part will be maintaining dry. This machine provide a fundamental contribution in softness to avoid breakage or modification of the leather during pulling over operations. Static or conveyor version.

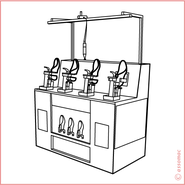

B03.08 - Pulling-over and lasting machines

It provides the shoe upper lasting, particularly focused on the front part of the shoe up to the last waist. The glue is applied by fixed injectors or moving nozzle or their combined action. A series of adjustable clamps maintains a perfect pulling and positioning of the upper on the insole. The operating cycle operating is completed by two plates that fold down the upper edge to the glued insole.

B03.09 - Machines to fix the uppers to the last

Nailing for fastening the upper to the last in the line of junction of the rear part of upper closing stitching, in order to not damage or perforating the shoe upper. The nail is extracted after shoe lasting.

B03.10 - Waist lasting machines

This machine is designed for lasting the shoe sides with manual control operation. Versions with glue, nails and nails with thermoplastic.

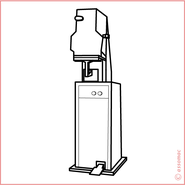

B03.11 - Heel seat lasting machines

Machine finalized to lasting the insole and upper in the area of heel seat by nails and/or glue.

B03.12 - Side and heel seat lasting machines

Sequential lasting machine of the shoe sides and the heel seat of insole and upper. It performs this operation through clamps, moving pressure pads, injection glue nozzle and/or application of nails.

B03.13 - Lasted shoe pounding machines

The machine smoothes and flattens the bottom of the shoe after assembly to facilitate the join/match of sole. Provide also the edge last leveling recovery. Solutions from manual version that is working through hard pounding roller to the automated tools that are managed through PLC control.

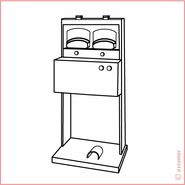

B03.14 - Ironing and stabilizing heat setters

Multifunction climatic chamber for lasted shoe treatments such as humidification and heating in order to reduce the various tension forces that are generated by the materials, particularly leathers. It irons and stabilizes the shoe adapting perfectly to the last.

B03.15 - Ironing machines with hot hair and roller

Machine equipped with a heated cylinder, that in combination with hot air and/or steam flow, is suitable to eliminate folds and creases remain on the upper leather.