A single material can replace entire systems of sensors, controllers and actuators. Programmable materials are real shapeshifters. At the push of a button, they change their properties in a controlled and reversible way and adapt autonomously to new circumstances. Researchers at the Fraunhofer Cluster of Excellence Programmable Materials CPM develop these programmable materials and, together with industrial partners, bring them to market maturity. One of the goals is to reduce the use of resources. [Formänderung auf Knopfdruck – chemie.de]

Matter plus microstructuring

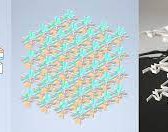

Materials for applications requiring a specific change in stiffness or shape are developed by researchers at Fraunhofer CPM, which is characterized by six leading institutes and aims to design and manufacture programmable materials. But how can materials be programmed? "Basically, we have two parameters: the base material – in the case of mattresses, thermoplastics, for other applications metal alloys, including shape memory alloys – and in particular the microstructure," explains Dr. Heiko Andrä, thematic speaker at the Fraunhofer Institute for Industrial Mathematics ITWM, one of the main institutes of Fraunhofer CPM. »The microstructure of so-called metamaterials consists of individual cells, which in turn consist of structural elements such as small bars and thin shells.« Thesize of individual cells and their structural elements varies randomly in conventional cellular materials such as foams, but is also variable in programmable materials, with a precisely defined, i.e. programmed, variation.

Materials can also react to heat or moisture

The change in shape that the material should have and to what stimuli it should react - mechanical stress, heat, humidity or even an electric or magnetic field - can also be determined by the choice of material and its microstructure. "Programmable materials make it possible to adapt objects to the respective application and thus to use things more multifunctionally than before. So they do not need to be replaced so often. This is particularly interesting when considering the savings in resource consumption," says Franziska Wenz, deputy thematic rapporteur at the Fraunhofer Institute for Mechanics of Materials IWM, one of the leading institutes of the Fraunhofer CPM. In addition, added value can be created by adapting objects to the individual needs of users.

The road to application

A single material can replace entire systems of sensors, controllers and actuators. The goal of Fraunhofer CPM is to reduce system complexity and resource utilization by integrating functions into the material. "When developing programmable materials, we always have the industrial product in mind, so we take into account, among other things, series production and material wear ," says Wenz. In addition, the first concrete pilot projects with industrial partners are already under way. The research team expects that programmable materials will initially replace individual components in existing systems or be used in special applications such as mattresses, seats, shoe soles and sportswear.